Maintaining right air humidity (RH) is important in various processes of poultry production. Either it is handling or hatching eggs, rearing pure lines, or managing broilers, layers, their parents& grandparent flocks.

Poultry industry has been depending upon evaporative cooling pads for quite some time, apart from cooling these also provide humidification benefits, but there are some limitations.

LIMITATIONS OF EVAPORATIVE COOLING PADS

- 1.Less precise control over temperature& humidity

- Not suitable for winter season

- Cannot be used at night time due to the risk of chilling

- Low temperature close to pads, while 2C higher at the farthest area.

- High Humidity close to pads, while humidity drops consistently going far from pads.

Farm raised chickens are sensitive commercial birds,to attain peak production parameters they need ideal care. With the advancement in poultry housing a relatively new technology i.e. misting system is gaining rapid popularity. The success is based upon their ability to maintainuniform RH & temperature throughout the shed irrespective of winter or summer season. Therefore misting systems have become an integral part of modern poultry rearing.

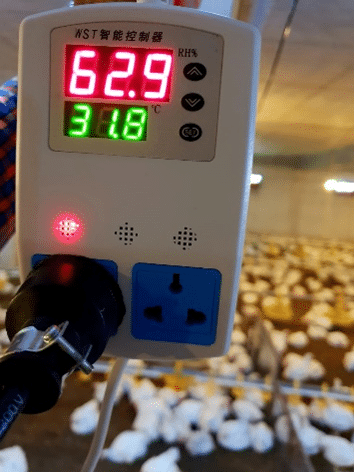

IDEAL RH FOR CHICKEN FARMS IS 60-65% WHILE FOR HATCHERY IT IS 85%.

RH below 50%at chicken farm leads to respiratory disorders, resulting in higher mortality, frequent use of expensive medicines & poor feed conversion. Hatchability percentage drops if RH falls below 80% at hatchery & newly hatched chicks may dehydrate if chicks holding room does not maintain RH around 65%.

HOW DOES MISTING SYSTEM SUPPORT POULTRY PRODUCTION?

Aves Mist humidification system is available to help poultry industry in many ways.

UNIFORM HUMIDIFICATION

Poultry thrive in the comfortable zone of air humidity. Aves misting systems are essential for hot dry summer as well as for winters to cater air dryness induced by heaters. We distribute misting nozzles equally across the poultry house to achieve uniform humidification. Our state of the art calibratable RH controller maintains RH within settable range. The system turns on automatically once RH falls below low set point & turns off automatically achieving high set point.A conducive environment strengthens the tracheal defense mechanism, to support mucociliary clearance.

Aves mist systems work on the basic principle of evaporation and we know that evaporation causes cooling i.e. humidification & cooling both go side by side. Unlike cooling pads, uniform cooling throughout the poultry house is an added benefit. Even distribution of numerous mist nozzles ensure uniform distribution of mist cooling in all areas to keep feathered fellows comfortable & vigorous.

Aves misting systems help to delay the use of cooling pads during summer season, a farm without misting system will be forced to use cooling pads even in the first week. Installing Aves misting system at the same farm can delay the use of cooling pads up to the third week. While it is also useful to operate in combination with cooling pads to minimize the temperature difference at later stage i.e. after 3rd week.

DOES MISTING SYSTEM INCREASE THE HEATING COST IN POULTRY PRODUCTION?

An individual trying to understand misting systems might think it to be true. To some extent this is true, but in a broader context it is not. Let’s explore why.

As we know there is a correlation between RH & temperature. Modern farming techniques have shown that required temperature for specific age may vary with varying RH. For example, day old broiler chickens require 33.5C at 50% RH, while the temperature requirement falls to 30C if RH increases up to 65%. This depicts that increase in RH lowers the temperature requirement of chickens.

Aves misting systems while increasing RH certainly reduce temperature, but this is compensated with a drop of temperature requirements of chicken itself. Therefore a slight difference is observed not a big one at all.

Utilizing Aves misting system in winters may increase heating cost up to 10%, contrary it saves up to 25% of a bigger cost, the medication cost. Healthier birds show a minimal cost of production so it’s a win win scenario.

DUST & AMMONIA REDUCTION

Aves misting systems help settle dust particles & allergens in the air, reducing airborne pollutants & germ count. Additionally, they aid in minimizing ammonia levels by binding with the gas molecules.This is essential for the respiratory health as well as gut health of poultry, ultimately leading to improved growth rates and higher production yields.

DISEASE PREVENTION

Aves misting systems contribute to creating a hygienic environment & reduce air bourne contaminants to reduce the risk of bacterial and viral infections among the flock. Thiskeeps medication cost at absolute minimum, by reducing the need to use antibiotics and expectorants.

BETTER FEED CONVERSION

Chickens raised in idealenvironment present top performance in terms of feed intake, growth, production, intestinal & respiratory healthreflected in better feed conversion ratio & profitability.

HOW TO CHOOSE MISTING SYSTEM FOR POULTRY FARM

Considering following info will be helpful to select right misting systems for your farm.

CAPACITY OF MISTING SYSTEM

Remember!An under capacity misting system will never be able to maintain the required RH i.e. 60%.Not all misting systems are the same, one needs to choose an appropriate capacity misting system to fulfill core requirement i.e. RH maintenance for all seasons, especially during the driest part of the year.

Outside humidity may fall up to 10% while temperature may be around 35-48C during the months of April, May & June. Generally we might be running at least 3-4 fans (tunnel ventilation) meaning 60,000 to 80,000 CFM air has to be moisturized in order to maintain humidity around 60%. We need to focus these conditions to design an effective misting system.

Misting systems are classified by their capacity to convert water into mist in one minute often calculated in liters &gallons. Therefore you would find misting system in various capacities: 0.5 liter per minute (LPM), 1LPM, 2LPM,4LPM,6LPM, 8LPM,12LPM,14LPM,18LPM, 24LPM.

1. Standard environment control house (20,000-25,000 sq. ft.)

A misting system with a capacity of 18LPM/360 nozzles or 12LPM/240 nozzles.

2. Battery Cage (60,000-90,000 bird)

A high pressure misting system with a capacity of 24LPM/480 nozzles.

3. Open shed without fans (3,000 sq. ft.)

A misting system with a capacity of 2LPM/40 nozzles.

4. Semi open shed with fans (3,000 sq. ft.)

A misting system with a capacity of 6LPM/120 nozzles.

Never opt for spray machines, mist fans, cheap spray systems usually used for bathing cows. All these short cuts have lead farmers to heavy economic losses instead of any benefits. It is a good idea to learn from advice instead of wasting money & precious time on such experimentation. Similarly never buy an under capacity misting system.

PERFORMANCE

A good misting system should produce fine mist that does not wet anything and the accessories should not leak.

AUTOMATIC OPERATION

Always select a misting system that operates automatically with a RH controller. Manually operated systems use timer to operate misting system. This results in uncontrolled RH often higher or lower than required levels.

ELECTRICITY CONSUMPTION

Power conservation is an important tool to curtail cost of production in poultry. Always compare the electric consumption amongst various misting systems before paying for it. Nothing beats advance misting systems in terms of energy efficiency.

QUALITY & DURABILITY

Higher the quality, higher will be the durability of a misting system. Although higher quality comes with higher price tag, still it remains economical in terms of prolonged & peaceful use. Cheap unprofessional misting systems can ruin your experience & misting can become a nightmare.

NO SHORT CUTS

Never try to skip even a smallest component of a misting system during installation. Short cuts may work for the time being, but they will cause a lot of trouble in future.

WARRANTY

Never buy a misting system that does not offer warranty, longer the warranty better it is. Good quality misting systems come with one year warranty. Confirm warranty claim policy & check for customer feedback.

WHY AVES MISTING SYSTEM

At Aves Fog quality is utmost priority,we use top gradeTaiwanese& Chinese parts for our mid pressure misting systems. Following are some important points that make Aves Misting Systems unique:

1) Aves Mist does not wet anything

2) Automatic operation based upon RH set point

3) Low power consumption i.e. 300 watts / pump / hour

4) III phase electric panel

5) Dry run & overload safety

6) Accurate RH controller

7) Most reliable water filtration (PPF)

8) Uniform distribution of fog either air is taken through inlets or through cooling pads

9) One Year Warranty and 24/7 after Sale Services

10) Variety of models: 1LPM, 2LPM, 4LPM, 6LPM, 12LPM & 18LPM

Drinking quality water with TDS level below 500 ppm is pre-requisite to avoid frequent nozzle clogging.However RO plant can be used if the TDS level is higher.

No one can beat us in, quality to price ratio, performance, durability and after sale services.