INDUSTRIAL HUMIDIFICATION

Air humidification is essential in various industries to maintain optimal environmental conditions for processes, materials, and human comfort. The need for controlled humidity arises from the specific requirements of different industries. Here are some industries that commonly require air humidification.

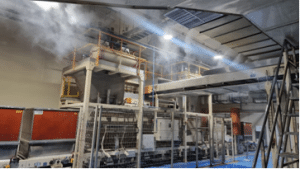

TEXTILE

Maintaining right air humidity is an integral part of processing natural fibers, to achieve peak production & to reduce imperfections in spinning, weaving, knitting, socks & garment manufacturing etc. Good humidification also helps to purify the air from pollutants like dust, fluff& chemicals etc.

PAPER

Humidification plays a vital role in paper manufacturing to prevent paper from losing moisture too quickly, reducing the risk of curling, cracking, or warping. This ensures the production of high-quality, dimensionally stable paper along with good air quality within the processing area.

TOBACCO

Appropriate relative humidityRH is essential for storing & processing tobacco, to preserve its quality and flavor. Controlled humidity prevents over-drying of tobacco leaves, reduces odor & improves air quality.

PRINTING

Maintaining optimal air humidity in printing environments is essential for preventing paper from absorbing or releasing moisture. These solvesissues like frequent paper jams, also improve print quality as well as the air quality.

TIMBER

Humidification is critical to prevent the drying out of wood to maintain its structural integrity. Appropriate air humidity creates a better environment at the furniture workshop by suppressing dust etc., and also provides adequate cooling to the workshop.

PAINTING

Right air humidity is important in paint booths to create ideal conditions for spray painting. Proper humidity levels ensure paint consistency, adhesion, and drying times, leading to a better finish and reducing defects in the painted surface.

ELECTRONICS

Precisecontrol of air humidity is essential to prevent electrostatic discharge (ESD) and ensure the reliable performance of electronic components during manufacturing.

At Aves Fog we have the insight of unique environmental requirements of each industry. Our trained technicians understand the subtleties of humidification much better. Experience & skills empower us to design effective fog humidification systems that contribute to enhanced productivity, product quality, and power conservation.

HOW DOES AVE FOG WORK?

Drinking quality water (TDS 300 ppm or less) is filtered & fed to Aves high pressure pump.It forces water through the delivery system & nozzles at 800-1000 PSI pressure to convert water into ultra-fine fog that does not wet anything. Billions of tiny droplets evaporate instantly to cool & humidify the environment. Pollutants like dust & fluff settle down by absorbing moisture that makes them heavier to stay airborne.

HOW IS AVES FOG BETTER THAN CONVENTIONAL METHODS OF COOLING & HUMIDIFICATION?

Conventional methods of humidification are obsolete considering higher electricity consumption & their inability to provide uniform humidification & cooling throughout the subject area.

Energy Efficiency

Aves Fog offers energy conservation 4- 25 times compared to conventional methods of cooling & humidification. Our fog humidification systems consume electricity as little as 0.15 units/hour to humidify 30,000 cubic feet indoor area. While a conventional system would consume approximately 3.75 units/hour. Isn’t Aves Fog amazing in terms of energy conservation?

Uniform Temperature & RH

Equal distribution of fog throughout the subject area helps to control theelectro static charge better & to achieve uniform humidification & cooling throughout the installed facility.

Better Air Quality

Aves Fog with larger surface area of its billions of ultra-finedroplets suppresspollutantsi.e. chemicals, dust &fluffmuch better than conventional methods, to improve air quality within the premises.

Customization

Tailored solutions for diverse industrial applications, providing flexibility and adaptability to meet your unique requirements

Captivating to watch

Aves Fog gives a futuristic touch to the installed facility to impress visitors by its aesthetic appearance.

Production Capacity

It helps to attain maximum productioncapacity by reducing costly disruptions & down time.

Product Quality

Enhances the quality of produce.

ROI

Quick return on investment.

Maintenance

Less laborious & low maintenance cost.

ESTABLISHED RESULTS

Revolutionize your industrial humidification with cutting-edge Aves Fog Technology.

0.3% increase in moisture regain is observed inthe conditioning department of spinning mills, making the return on investment as quick as 3 months.

For digital printing in textile sector, Aves fog offers the most advance dry fog (5 micron) humidification. It consumes electricity as little as 0.1 unit/ hour, lasts 3 times more than humidifier.

Aves fog expends 4 times less electricity to maintain right humidity in tobacco industry & weaving.

WATER QUALITY

Drinking quality water with TDS below 300 ppm is pre-requisite for Aves Fog, to avoid frequent nozzle clogging. We use cleanable nozzles with additional filter to minimize clogging issues.

A variety of Reverse Osmosis Units are available to purify water in case of higher TDS level.

WHY AVES FOG?

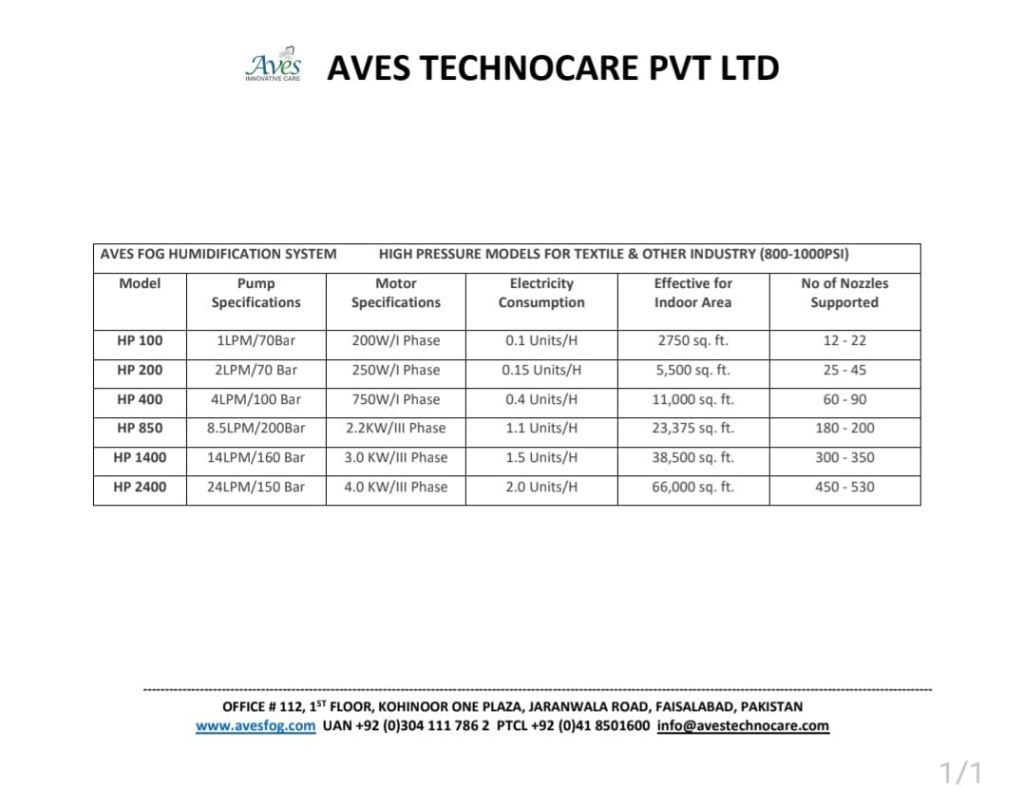

Diverse Models

Aves high pressure misting systems are available in various capacities: 0.5LPM, 1LPM, 2LPM, 4LPM, 6LPM, 8 LPM, 12LPM, 16LPM, and 24LPM.

Large Inventory

By virtue of large inventory we are capable to meet short lead time projects.

Quality is Utmost Priority

Use of High Pressure (100-150 bar) Italian Pumps ensure durability & unmatched performance.

High Pressure Misting accessories (120 bar) are manufactured on demand from top manufacturers in Taiwan.

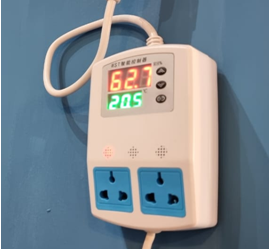

Use of calibratable RH controller provides accurate estimation of humidity.

Innovation

Our R&D department works round the year to convert new ideas into reality and to improve the performance & durability of existing products, to maintain Aves Fog’s excellence & reliability.

Skills & Experience

We have vast experience with high pressure misting systems & their application in industrial humidification & cooling. Our solutions are comprehensive & energy efficient.

Warranty & After Sale Services

One year warranty is offered for our products & maintenance services remain available 24/7

No one can beat us in quality to price ratio, skills & experience, after sale services& Durability.